Justrite Safety Cabinets

Justrite cabinets surpass Australian Standard Compliance AS1940. They are the only cabinets that have undergone fire testing and received a rating from FM Global, a performance standard recognized by insurance companies. These cabinets are rated for 10 minutes, ensuring that the internal temperature does not exceed 163 degrees Celsius—a distinction that sets them apart from other cabinets in Australia.

Features

Justrite manufactures Storage Cabinets that comply with the applicable Australian Standards with great precision. Featuring a Powder Coat paint finish, these cabinets boast a superior high gloss appearance that minimizes the impact of corrosion and humidity. The durable finish is resilient against abrasive wear and tear. The three-point locking mechanism in the cabinets has a fail-safe closing mechanism to ensure complete safety and security. Specially designed locking bars prevent bending and distortion, ensuring a secure locking effect. Furthermore, the cabinet is equipped with a locking mechanism that enables you to padlock it for added security.

Justrite Storage Cabinets have self-closing sequential doors, ensuring a secure seal as the left door closes before the right door. The full-length door piano hinge guarantees a durable and sealed barrier to protect the cabinet’s contents. Adjustable leveling feet at all four corners allow for precise positioning. The shelving design enables ventilation throughout the cabinet, and troughs on each shelf collect spills, directing them away from products on lower shelves. Shelves are adjustable in 76mm increments, with polyethylene shelves provided for Corrosive Cabinets.

Justrite Storage Cabinets come standard with a 150mm deep fully sealed sump designed to contain spills or leaks within the cabinet. The self-closing mechanism is housed in the roof of the cabinet, maximizing storage space and preventing damage or alignment issues. Adjusting the cabinet closure mechanism is a straightforward process that involves removing the four self-tapping screws securing the roof.

The Justrite Storage Cabinets feature dual vents that contain built-in flash arresters. These vents actively ensure the secure storage of flammable liquids and materials. Additionally, when necessary, these vents will actively pipe away hazardous vapors. The package includes Thermal Fusible Door Links, which keep doors open while loading and unloading. These links automatically disconnect at 74 degrees Celsius to facilitate the easy closure of doors. The cabinets also feature a double-wall thermal barrier with 1.2mm steel thickness and 40mm air wall spacing. Most cabinets are available ex-stock, meeting your requirements promptly. Additionally, Justrite offers a 10-year manufacturing warranty for these cabinets.

Please see below a list of cabinets available to order online

Corrosive Cabinets – White Polypropylene Construction

In order to ensure safety, it is recommended to use poly-constructed cabinets designed for the storage of highly corrosive chemicals. Some examples of such chemicals include Phenol, Nitric Acid, Sulphuric Acid, and others. These cabinets are manufactured to comply with AS3780 standards for the safe storage of corrosive substances.

Click here for pricing and more details

Corrosive Cabinets – Blue Powder Paint Finish

Corrosive Substance Storage Cabinets come equipped with a Polyethylene tray on each shelf to contain spillages. They can safely store corrosive chemicals and withstand fires, providing a secure storage environment. These cabinets adhere to AS3780 standards for the safe storage of corrosive substances. If you are dealing with chemicals like Phenol, Nitric Acid, Sulphuric Acid, or others with highly corrosive vapors, it is recommended to consider the Poly constructed cabinets for safe storage.

Click here for pricing and more details

Corrosive Cabinets – Blue Polyethylene Construction

Corrosive Cabinets – Blue Polyethylene Construction

If you are dealing with chemicals like Phenol, Nitric Acid, Sulphuric Acid, or other substances with highly corrosive vapors, it is recommended to consider these Poly constructed cabinets for safe storage.

Click here for pricing and more details

Shelves to Suit Corrosive Cabinets

Click here for pricing and more details

Flammable Storage Cabinets – Yellow Powder Paint Finish

Flammable Safety Storage Cabinets offer a secure, convenient, and compliant solution for storing various hazardous materials. These cabinets pass the FM rating test and exceed the Australian Standard AS 1940 for fire-resistance. They enhance workplace safety by providing easy access to stored products, eliminating the need for time-consuming and potentially risky trips to external storage facilities.

Click here for pricing and more details

Shelves to suit Flammable Cabinets

Shelves to suit Flammable Cabinets

Click here for pricing and more details

Organic Peroxide Cabinets

These cabinets adhere to AS 2714 standards and feature a sump capacity equivalent to the total volume of the cabinet’s contents. The cabinets are designed to open their doors outward for added safety in the event of an explosion. The maximum capacity of these cabinets is restricted to 100 kg or 100 L.

Click here for pricing and more details

Oxidising Agent Cabinets

Oxidising Agent Cabinets

According to Australian Standard AS 4326, the storage of Packaging Group 1 substances is limited to 50 kg or 50 L in a cabinet. You can store up to 250 kg or 250 L of Packaging Group II substances in a single cabinet.

Click here for pricing and more details

Pesticide Cabinets – Green Powder Paint Finish

Cabinets designed for the safe storage of pesticides typically come with specific features to ensure the secure containment of these substances. It is recommended to install safety measures such as a safety shower and eye wash in areas where pesticide packages are opened. These precautions aim to enhance safety and minimize risks associated with handling pesticides.

Click here for pricing and more details

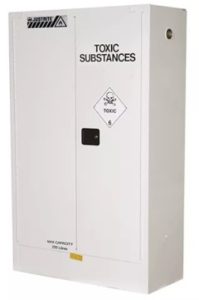

Toxic Substance (Poison) Cabinets

Toxic Substance (Poison) Cabinets

Cabinets designed for the safe storage of toxic substances, as per AS 4452, adhere to specific safety standards. Installation of safety showers and eye wash stations is mandatory in areas where toxic substances are handled. Ensuring the safety of individuals handling toxic materials and minimizing risks associated with potential exposure requires the implementation of these crucial measures.